In the darkness of the night, the flashing bright light, sometimes wildly beating, sometimes gentle, gradual change, as the darkness of the sea in the lighthouse flashing, and like the stars in the deep night.

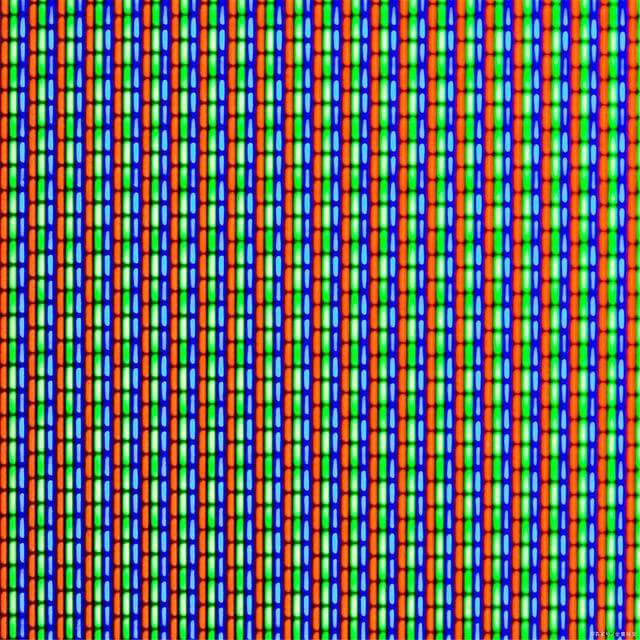

Looking at the changes of each light color such as red, orange, yellow, green, cyan, blue, and purple, are you wondering how this is done?

The process control of LED beads in the production process determines the luminous light color of LED beads as single or multi-color. There is a multi-color function of the LED beads mainly through the change of current to control the light color of the lamp; by controlling the current can achieve red, green, blue, and any visible light color. Various combinations of light beads can achieve the color change control of the whole lamp on the substrate to achieve different light effects.

Table of Contents

ToggleWhat is the difference between RGB and RGBW?

RGB color mode is a color standard in the industry. RGB is the color that represents the three channels of red, green, and blue, and this standard includes almost all the colors that human eyesight can perceive, and it is one of the most widely used color systems at present. RGB mode color system is widely used in many industries, such as lamps, smartphones, computers, TVs, LED displays, etc.

RGBW has two technical advantages: firstly, it consumes less power for the same brightness, and secondly, it can achieve higher brightness with the same power consumption. Therefore, lamp manufacturers are also interested in this technology because it fundamentally reduces the power consumption of LED beads. The brightness can reach the level of power consumption required before. RGBW has better light transmission than RGB, and white pixels do not absorb a certain amount of light like RGB, improving the efficiency of light. Although RGBW technology has great advantages, it also has defects. For products like monitors, it will reduce the actual physical resolution.

The difference: RGBW is the addition of white pixel W to RGB. RGBW is brighter than RGB, with better light transmission and lower power consumption; however, the purity and saturation of single color will be reduced.

Can I control LED strip lights with a phone?

Yes, this is possible.

Connect the strip lights to the LED controller, install the APP, find the signal from the LED controller on your phone, follow the instructions, and then you can control the strip lights with your smartphone.

How to connect the RGB light controller to your smartphone 2021?

What is the difference between LED and SMD?

. High transmittance, indoor lighting is not affected, the picture display effect is perfect.

As we all know, conventional SMD display is not light-transmitting, which will affect the lighting of the building. The transparent LED display adopts side light-emitting display technology. The light bar is almost invisible to the naked eye from the front, which greatly improves the permeability, and the whole picture display effect is very cool.

.Lightweight design, saving the cost of steel structure

SMD conventional display 42kg per square meter, when the screen area is too large, the screen steel structure and the original building structure is a significant challenge. Transparent LED display can be installed vertically and independently, without glass. If installed behind the glass curtain wall, it can be directly attached to the curtain wall steel structure installation, its very lightweight of 16kg/㎡, the weight demand on the steel structure is very low.

.The strip light structure can be shaped design

SMD conventional display to do shaped products will be subject to the limitations of its box structure; splicing shaped has a little defect, and there will be splicing seams. A transparent LED display can be custom spliced into a perfectly shaped screen. The surface transition is natural and beautiful. The product screen body can be set to support the cylindrical, round table, triangle, arc, and other types of shapes.

.For outdoor display applications, indoor installation, outdoor viewing

SMD conventional display installed indoors will block the sun and line of sight. Transparent LED display for outdoor screen applications, indoor installation, outdoor viewing, do not worry about waterproof and UV protection, the product performance is very stable.

. Hidden installation does not affect the building shape.

SMD conventional screen in the construction of large-scale steel frame structure, time-consuming and labor-intensive, impacts the building modeling and aesthetics. Transparent LED display in the installation of a small amount of construction can be easily and perfect combination with the wall, no damage to the wall, and improve its overall appearance and aesthetics.

.Easy maintenance, can support hot-swappable, light bar maintenance

SMD conventional screen body problems, most of them are post-maintenance treatment or the entire module or box disassembly for maintenance. Transparent LED display in the maintenance only need to replace a light bar, simple and quick operation, reduce maintenance costs

The principle of LED controller

LED lights usually contain an array of LEDs. The LED controller is based on a pre-set program that can control the switch of each position in the LED light circuit so that the LED array glows regularly, thus displaying specific text or graphics. These LEDs are connected in series, then the constant current power supply should be provided by the drive; because the brightness of each LED is determined by its current, the use of the current must be strictly controlled to ensure the normal operation of the LED lights

LED controller is the chip processing control LED lights circuit in various switch positions, mainly divided into the following categories.

Low-voltage LED products high-power controller —- is generally designed for voltages of 12V-36V, the number of LEDs in each circuit 3-6 in series. Advantages are low-voltage, simple structure, easy to design; disadvantage: the product is large scale when the current is very large, the need to configure low-voltage switching power supply.

High voltage LED product controller —- design voltage is AC/DC 220.

Related Articles